The most important part of the answer has little to do with money, at least over the long run.

Australian Manufacturing is back in the media.

Earlier this month, Australia’s Prime Minister Anthony Albanese addressed the Queensland Media Club about his government’s vision for a Future Made in Australia.

His speech covered a lot of territory as he explained why the Australian government is “investing in manufacturing to make more things here.”

His speech inevitably sparked criticism.

Some say trying to diversify Australia’s narrow industrial structure will fail.

Others say this latest recasting of national industry policy lacks essential details.

On the surface, some probably see this as an attempt to compete with mass manufacturing giants such as the USA and China.

Having spent my working life in new-car engineering and manufacturing, any attempt by Australia’s government to drive our economy’s secondary sector is a good thing.

But amongst all this, perhaps some critical long-term factors are being overlooked, attributes you’ll find at work in advanced manufacturing nations such as Germany.

A rocky past

Australia has had a mixed relationship with its manufacturing sector these last few decades.

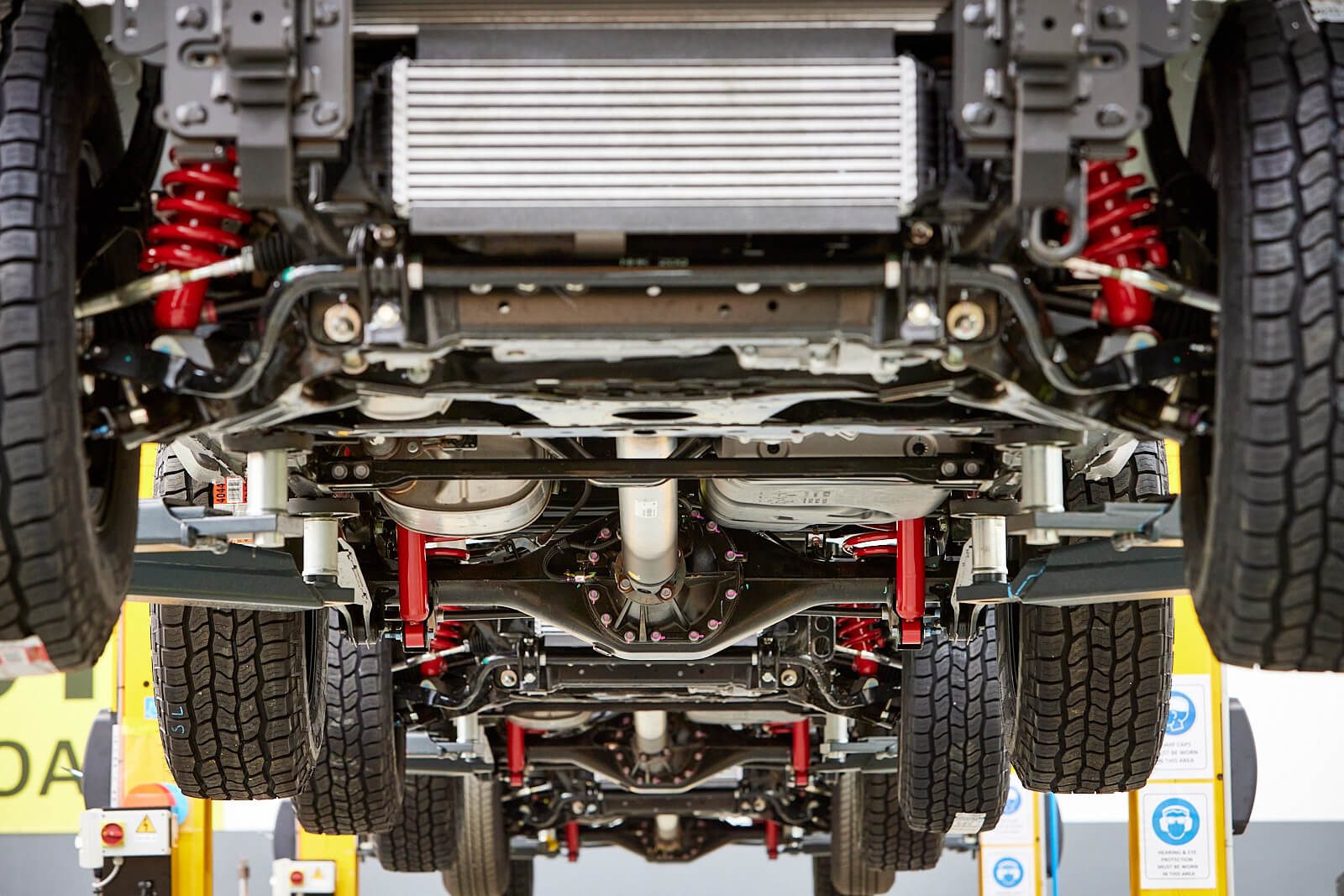

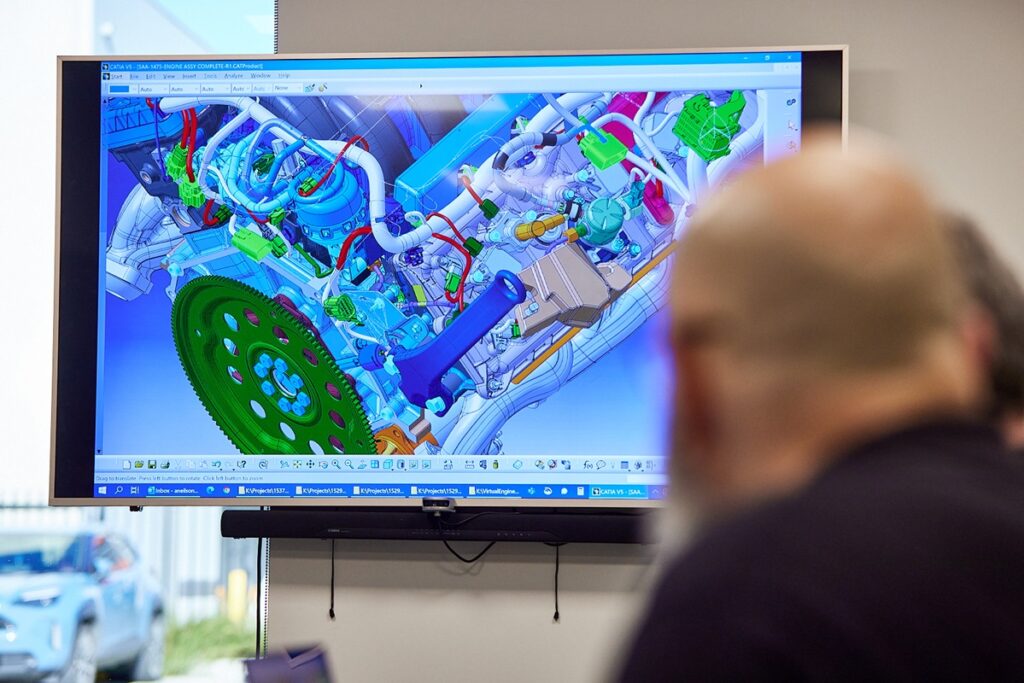

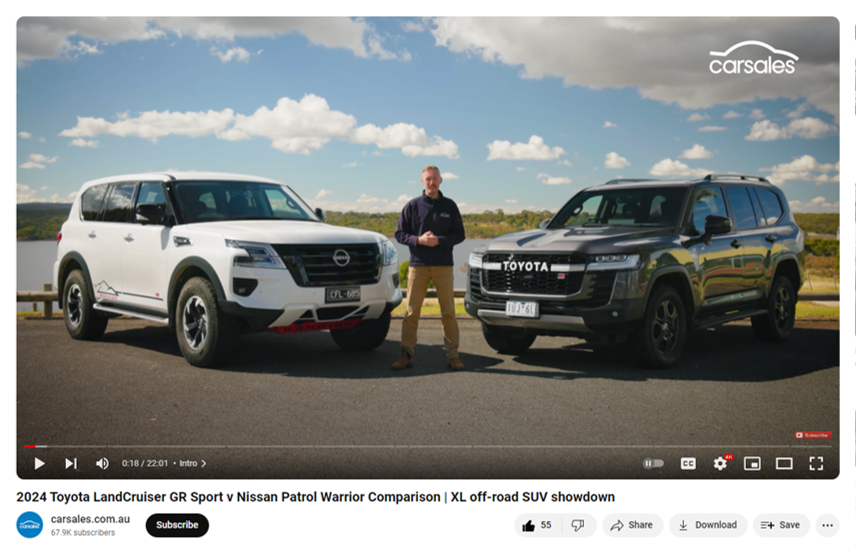

Premcar was developing and building cars for Ford under the Ford Performance Vehicles (FPV) brand when the ‘big three’ (Toyota, GM-Holden, Ford) stopped their local new-car assembly operations in 2016-17. Since FPV ended we’ve gone on to grow much further with various other major automakers.

There’s no question lower-cost manufacturing overseas has eaten into Australia’s ability to compete globally, but this isn’t a reason to avoid growing our local manufacturing industries.

It’s because manufacturing isn’t solely about the money it makes for a society, it’s also about the society itself.

Spend time in a major German carmaking city like Stuttgart and you can see the positive effects a complex manufacturing economy has on its social fabric.

Universities and trade schools develop challenging education programs to train the people needed to power these businesses. Companies and supply chains sprout and grow to support them. New intellectual property achievements become saleable commodities.

German traits such as ‘Detailverliebtheit’ (attention to detail) and ‘Leidenschaft’ (passionate fervour) are said to have influenced the long-standing success of local automakers.

It’s fair to say they still do.

But their local culture has cultivated these drivers over time, thanks in part to their ever-developing manufacturing abilities.

Manufacturing is very much about advancing people and the societies they create. It’s a big reason why manufacturing is worth pursuing in Australia.

A society skilled and experienced in making its own things is an advanced society. And it will keep advancing because being capable of solving one challenge creates skills to solve others, and so on.

A rock-solid future

When Australian mining prospector Lang Hancock flew his little aircraft through a deep gorge along the Turner River in Western Australia’s remote Pilbara region back in November 1952, little did he know he had just spotted the world’s largest iron ore deposit when he glanced out the small window to his left.

If it wasn’t for an unusually late departure that day, and low cloud forcing him to take a different flight path, he might not have set in motion Australia’s single biggest export industry.

In a 1969 ABC documentary, geologists were reported to have said this vast iron ore supply amounted to “a hundred million, million tonnes” and “enough to supply the whole world, at the present rate of use, for 140,000 years.”

Luck might have led Lang Hancock to find Australia’s economic future, but we can tailor Australia’s manufacturing sector exactly how we want it, and we can use it to augment the country’s future prosperity and security.

And despite the conjecture about the PM’s speech, there is one indisputable fact, and that is time. The clock is ticking. As the PM said, “This isn’t something that happens overnight, it’s the work of a generation. But the preparation for what comes next, has to start now.”

Bernie Quinn – Engineering Director, Premcar Pty Ltd

About Premcar:

Premcar Pty Ltd is a leading Australian vehicle engineering business that specialises in the automotive, defence and aerospace industries. For more than 25 years, global car-makers have made Premcar their go-to partner for the complete design, engineering and manufacture of niche-model new cars, full-scale new-vehicle development programs, and electric vehicle (EV) conversions and manufacturing. Premcar’s body of work is extensive. It is the name behind more than 200,000 new cars and 55,000 new-vehicle engines. The company has delivered technical advancements and sales success for major car brands from Europe, the USA, Japan, China and Australia. Visit premcar.au.

Follow Premcar on Instagram – @premcaraustralia

Follow Premcar on LinkedIn – @Premcar Pty Ltd