Carmakers navigate a risky maze on the road to commercial success, and mistakes along the way can be expensive.

Nuts and bolts can do amazing things.

They not only hold things together, they can – depending on their materials and design – withstand incredible forces.

For example, a grade 10.9 M8 bolt (8 mm diameter) with a standard-pitch thread can take more than three tons of tensile proof load. That’s more than the weight of a Nissan Patrol Warrior hanging off the end of it.

But what happens to a product when that bolt isn’t tightened properly? Or the wrong size? Or someone forgets to install it?

In the world of carmaking, those questions spark lots of scenarios – and stress.

Real-world insights

Some time ago, Nottingham Trent University in the UK released some great insights into the practical realities of product development.

Their research focused on carmaking. It’s fascinating reading, especially for anyone outside the automotive industry.

Here are some highlights:

Automotive product development is high in complexity and high in risk

In a 2×2 grid, the report compared product development in different industries according to complexity and risk. Here are some examples they gave:

- Low complexity and low risk: Commodities, such as paper and glass

- High complexity and low risk: Electronic goods and white goods

- Low complexity and high risk: Fashion, textiles and food/drink

- High complexity and high risk: Aerospace, major construction and automotive

It’s a fair assessment.

Their presentation also outlined the Triangle of Compromise (which balances time, cost and quality) and this small but important three-way map underpinned all of their following points.

A small mistake in Product Development can cost the reputation of the company

Here they cited the example of the first generation 1997 Mercedes-Benz A-Class.

This innovative five-door hatchback was a radical new design for the world’s oldest carmaker.

Its compact size was ideal for crowded European cities.

It’s sandwich floor chassis had an upper and lower layer. Inside were common under-bonnet items such as the battery, freeing up space to create a cleverly packaged cabin.

But when Swedish magazine Teknikens Värld performed their ‘elk test’(a swerve-and-avoid manoeuvre that simulated dodging a moose on the road) the car flipped over.

Mercedes-Benz recalled all of the examples they had so far sold. They suspended sales of their newest model for several months while they fitted it with electronic stability control and modified its suspension.

According to The Economist, Mercedes-Benz had spent DM 2.5 billion (US $1.4 billion) developing the A-Class. After the ‘elk test’ it spent an extra DM 300 million (US $165 million) to fix it.

A serious mistake in Product Development can cost the company

The example given here was the story of the Ford Edsel, the large and unattractive 1950s sedan named after Henry Ford’s son.

Ford was so confident of the Edsel’s expected success the company even established its own Edsel-branded division devoted to its creation.

TIME magazine reported in 1957 that Ford dedicated 10 years and US $250 million (that’s more than US $2.5 billion today) to develop the Edsel.

Ford expected to sell around 200,000 Edsels in its first year. When this new model series launched in 1958, the public reception and sales figures were so poor that by late the following year the decision was made to close the program.

Edsel sales totalled only 116,000 by the end of its short production life, which probably should have been around 10 years, had it succeeded.

Repeated mistakes in Product Development will cost the company

The ongoing Takata airbag inflator product safety recall is the most recent example to highlight this point.

This is the world’s largest automotive recall, affecting an estimated 100 million vehicles around the world. It is the most significant compulsory recall in Australia’s history, with more than four million affected Takata airbag inflators and involving more than three million vehicles.

As of March 2021, the Australian Competition and Consumer Commission (ACCC) announced a recall completion rate of 99.9 percent.

Achieving that has taken a vast long-term effort by many people and organisations. But the safety recalls continue.

The consequences for Takata – legally, financially and reputationally – have been deep.

In February 2017 Takata agreed to pay a US 1$ billion fine to settle its US investigation. It filed for bankruptcy in the US and Japan four months later. Most of its assets were then taken over by Key Safety Systems, which has since renamed to Joyson Safety Systems.

Superior capability in Product Development will renew the company and increase its profit over time

Nottingham Trent University illustrated how one Japanese carmaker’s program costs were consistently 50-75% of European and US carmakers. In fact, their lead times (the time it takes for the idea of a new car to become a showroom reality) were about half.

They also drilled into the development time it takes for a new-model car to reach the market.

Eight major automakers were given as examples. The time to market varied from 32 months to 51 months but the Design Freeze times (the number of months taken to finalise a new car’s design) were the most revealing.

The brands with the shortest Design Freeze times had more time to focus on a new car’s engineering and manufacturing quality, which correlated with higher scores in independent Quality Surveys such as JD Power.

The Long Game

The message was simple: Successful Product Development – and correctly balancing time, cost and quality – gives automakers long-term advantages.

But the effects of releasing new products with engineering or manufacturing faults can be catastrophic.

Cars that aren’t correctly developed or correctly built can expose so many people to risks, from road users to shareholders.

One Product Safety Recall can be followed by another. And these can be accompanied by lower-profile ‘service campaigns’, where a new-car importer instructs owners to return their cars to their nearest dealer for rectification of what are often non-safety-related technical problems. These can involve thousands of cars at a time. And a lot of money.

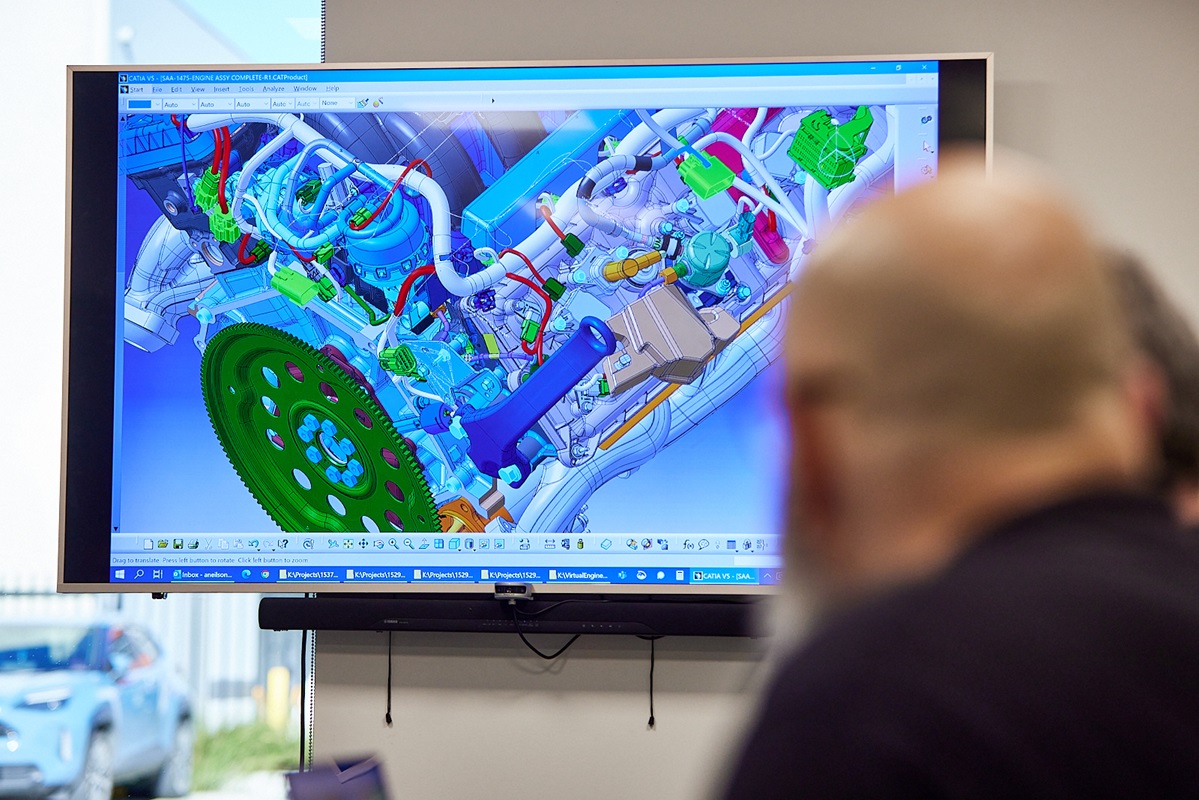

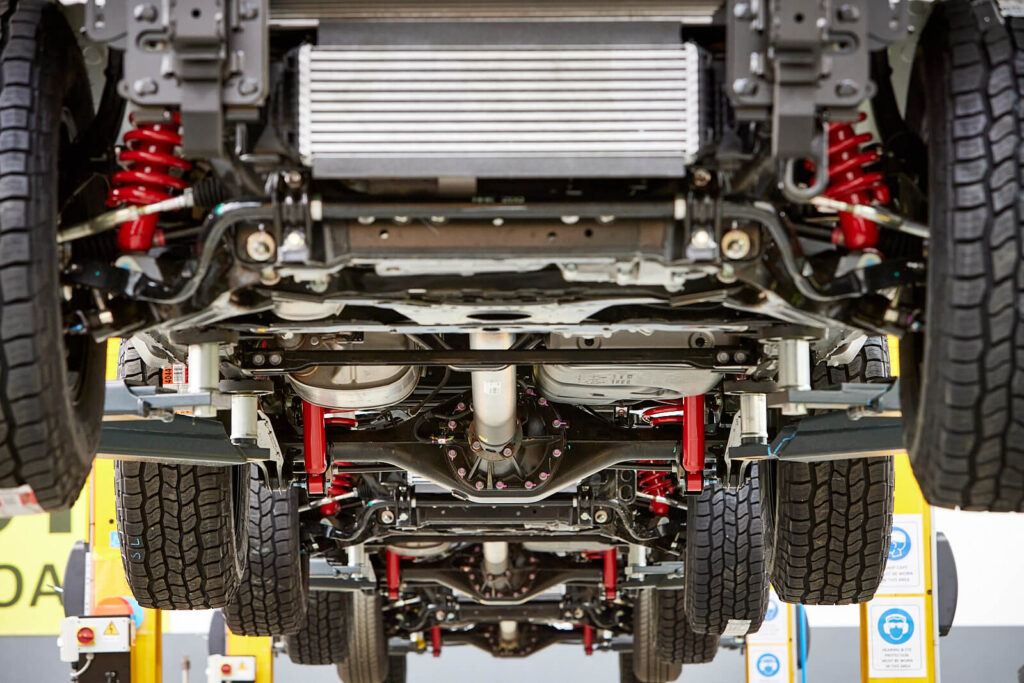

These are all reasons why Premcar has both new-car engineering and manufacturing under one roof.

It’s so they can both work together during product development and manufacturing.

The payoffs are substantial. It’s why major carmakers have both in-house.

Getting product development and manufacturing right builds intangible essentials, such as trust. Trust can take decades to build, but one mistake to extinguish.

Trust can be powerful enough to attract generations of new-car buyers.

But it usually can’t withstand the force of negative public perception.

And alongside the need for product safety and consumer protection, trust is a powerful reason to get the nuts and bolts right.

Because unlike that 8 mm bolt’s ability to withstand the tensile weight of a three-tonne 4×4, a carmaker’s brand can snap with one engineering or manufacturing mistake.

Bernie Quinn – Engineering Director, Premcar Pty Ltd

About Premcar:

Premcar Pty Ltd is a leading Australian vehicle engineering business that specialises in the automotive, defence and aerospace industries. For more than 25 years, global car-makers have made Premcar their go-to partner for the complete design, engineering and manufacture of niche-model new cars, full-scale new-vehicle development programs, and electric vehicle (EV) conversions and manufacturing. Premcar’s body of work is extensive. It is the name behind more than 200,000 new cars and 55,000 new-vehicle engines. The company has delivered technical advancements and sales success for major car brands from Europe, the USA, Japan, China and Australia. Visit premcar.au.

Follow Premcar on Instagram – @premcaraustralia

Follow Premcar on LinkedIn – @Premcar Pty Ltd