Certain car brands are using product localisation to boost their sales. This is how Premcar achieves it for them with suspension and handling enhancements.

Selling new cars is intensely competitive and Australia is Exhibit A.

60-plus new-car brands. Almost 400 models. All for a market of ‘only’ about 1.1 million sales a year.

The US offers a similar number of car brands but it sold 15.5 million new cars in 2023.

You can see Australia is competitive.

Brands big and small, old and new, are clambering more than ever to secure buyers in the Australian market.

And it’s a fast-changing market.

Vehicle electrification means new cars are changing.

The rapid rise of new automakers means the brands selling them are changing.

Generation Z are now new-car buyers, which means customer profiles are changing.

Just one of those last three sentences is enough to rock the global car industry.

But all three occurring at the same time means automakers are being forced to adapt.

One way some brands are adapting is with local-market new-vehicle enhancement programs.

Premcar specialises in these. Carmakers everywhere have used us for local-market enhancement programs for almost 30 years.

Off the Rack vs. Made to Measure

You can liken new-car enhancement programs to clothing. A suit’s a great example.

You can buy a suit ‘off the rack’, which means you choose a size, style and colour – and then wear it.

A made-to-measure suit, however, is the same suit that’s undergone some careful changes to create a much better fit for the customer.

The main difference is this: Thanks to some small changes, a made-to-measure suit has a huge product-based advantage over its off-the-rack competitor.

When a carmaker looks for a product-based advantage in a particular market, it’s the brand’s official importer that tends to ask the initial questions.

They’re the people under daily pressure to create sales and profits.

The first question they usually asks us is: ‘What changes can you make to our car?’

Then this one: ‘What can you do to the ride and handling?’

‘Ride and handling’ is a big topic, especially in markets like Australia. Globally developed new cars don’t always perform so well against this country’s unique road conditions.

This is how varied Australia’s road conditions are: If I turn right out of Premcar’s driveway in suburban Melbourne, I can be driving on smooth new roads, rough bitumen, freeways, compacted gravel roads, loose gravel roads, fire trails and off-road tracks – all within one hour.

Ride and handling

There are inches-thick engineering text books written about ride and handling.

It’s surrounded by layers of mathematics equations.

It’s even referred to as a ‘black art’ by some people.

But one word underlines its importance: experience.

Ride and handling determines the experience of driving a car. Any car.

And for a new-car buyer, this experience will establish and confirm almost everything in their purchase decision.

During a test drive, here’s what the buyer is often thinking:

Does the product match the promises in the brochure? Does it match the badge? Does it equal my expectations?

And this one:

Do I feel a bit let down when I drive it?

The road to a sale

That last question is a big one. As objections go in the new-car sales process, it’s a killer.

Price discounts might compensate to get that buyer’s sale. Or that month’s finance offer might secure their signature. But both of these miss the point.

The point is enterprise.

For any carmaker, its official importers, distributors, dealers and agents, the point is to create a successful and sustainable business. And the best way to achieve this is by offering products buyers want.

Products, not prices.

We all know buyers want value. Great products create value. Lower prices don’t.

And because the experience of a new car is largely down to its ride and handling, suspension tuning plays a big role in its perceived value.

Which is why local suspension tuning programs are so important in different new-car markets.

Suspension tuning: some quick background

This whole process begins with some logic.

If you replace specific suspension components on a new-car model series with ‘other’ or ‘brand-name’ components, depending on the parts chosen you’ll probably see measurable improvements in the desired performance.

But there’s a good chance you’ll cause problems. Some of them can be serious.

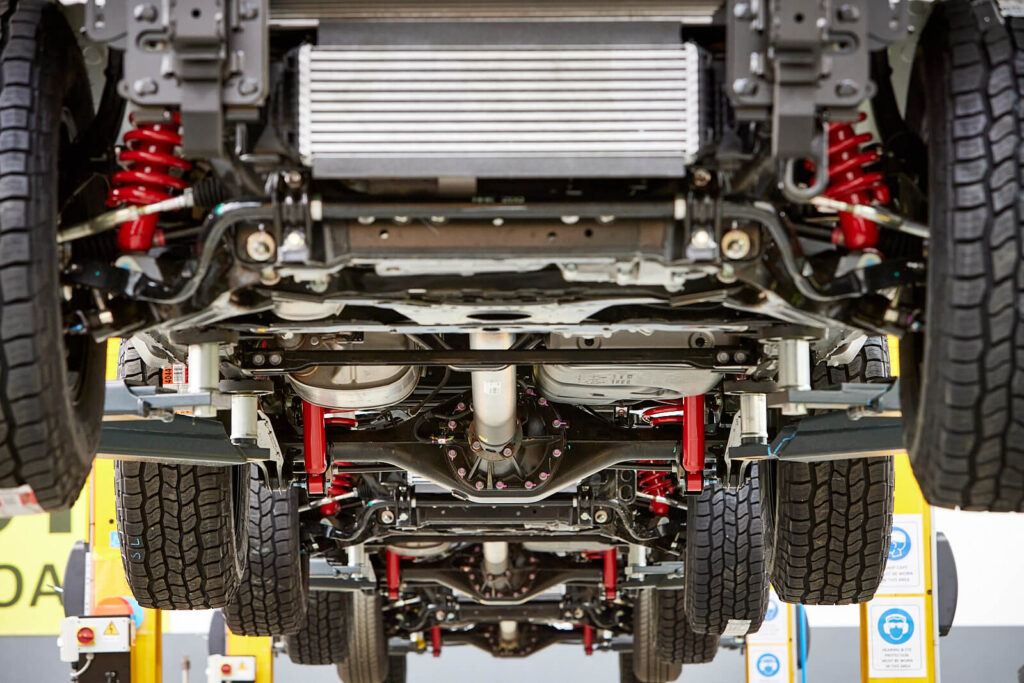

This is why any technical changes in a new-car enhancement program need to be fully integrated.

‘Fully integrated’ means making sure all of these new components and systems work together perfectly – especially with existing systems and parts.

(Oh, and by the way, achieving this isn’t simple. And a big part of ensuring you’ve achieved this integration is with the right engineering testing.)

The next thing to address is bandwidth.

We never – I repeat, never – develop new cars and enhancement programs that operate outside the boundaries of a vehicle’s existing mechanical design.

We call this boundary a car’s bandwidth.

We can expand this bandwidth to improve a sports car’s handling abilities, an electric car’s ride quality, or a 4×4’s off-road abilities; and we can achieve these without altering neighbouring attributes.

We can enhance a 4×4’s off-road performance without degrading it’s ride and handling.

In fact, we can raise all three at the same time. And the result won’t cost the earth (for the carmaker or their customer).

And it will all be fully integrated and inside the vehicle’s physical (as in physics) bandwidth.

Enhancing suspension performance for local conditions and tastes

OK, nuts and bolts time.

This is the topic most people want to know about.

I’ll cover suspension springs, anti-roll bars, dampers, and jounce bumpers. I could add more but I’ll confine this post to these four topics.

Primary ride and secondary ride

A vehicle’s primary ride is how well it ‘copies’ or follows the road’s surface.

For example, a super sports car has a high frequency ride. This is because it sucks down over every undulation in the road for high-performance driving. This is a positive attribute for a car of this nature.

The down side is the occupants’ body movements in the seats become faster. And their head toss movements more acute. These are uncomfortable.

The buyer of a super sports car might accept this as OK. A family SUV buyer or EV hatchback buyer won’t. It’s why every vehicle type has specific attribute targets.

Primary ride control is like a see-saw (or a teeter-totter for US readers): it’s about seeking a balance between control and comfort.

Depending on the vehicle, sometimes we can raise the height of the seesaw’s lever (or fulcrum) to achieve better control and comfort, but the critical goal remains: to develop the right balance of both to give the local segment’s customers what they prefer.

Secondary ride, on the other hand, is how the vehicle reacts to the smaller impacts from the road’s surface. These are the movements caused by the road’s fine undulations and patchy surfaces.

The goal here is to isolate these from the vehicle occupants as much as possible.

Springs

When we develop a suspension tuning package for a carmaker, we study the vehicle’s existing spring rates (the amount of load needed to compress the spring every millimetre).

We specifically study the balance and ride frequencies for the front and rear to ensure they’re in the ideal range for the ride quality result being targeted.

We might investigate progressive-rate springs (which become firmer the more they are compressed.) These are usually good for larger vehicles. Depending on the vehicle type, it could be dual-rate or even triple-rate springs.

With larger vehicles we avoid compromising their curb weight ride characteristics and their GVM ride characteristics. That is, what the car’s like to drive when it’s got only a driver onboard compared to when it’s fully loaded with people and cargo.

Anti-roll bars

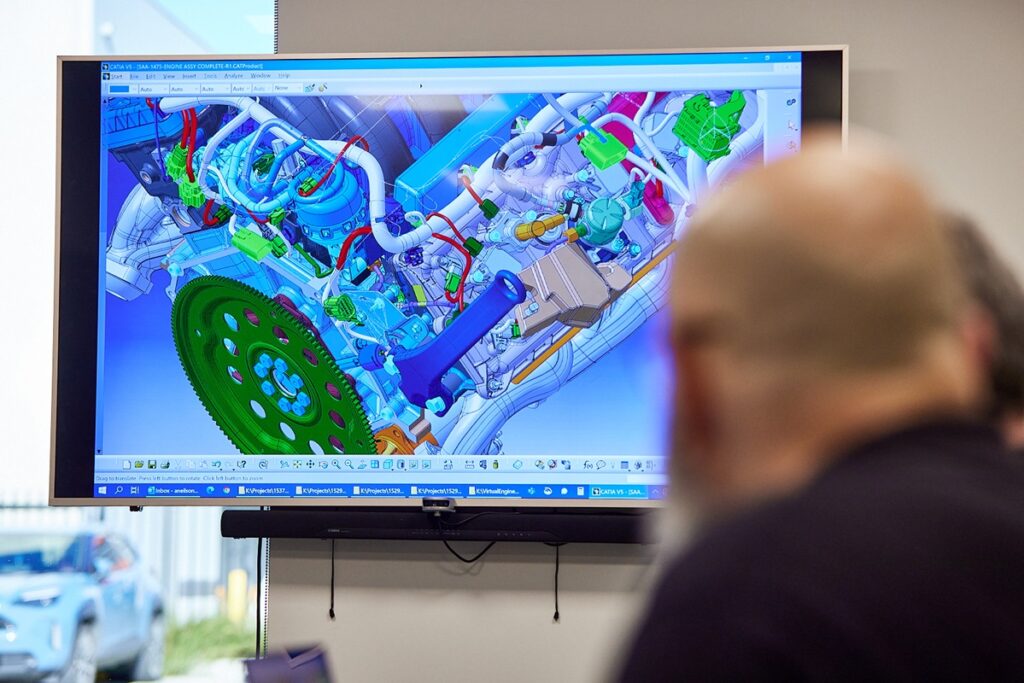

Premcar performs software-based simulations to help fine tune a vehicle’s ride frequency and spring rates to get to the target solution. Our chassis engineers use ADAMS Multibody Dynamics software.

We study the vehicle roll angle targets we need to achieve and balance these against the target ride characteristics. A stiffer anti-roll bar can mean less roll angle, but it might upset the vehicle’s cornering stability, or reduce the wheel articulation.

Once again, it’s about creating balance.

When it comes time to develop test hardware, prototype anti-roll bars of differing thicknesses and stiffness are created with suppliers.

We might develop four or more of these for the front, and the same number for the rear. (The number depends on numerous factors).

And then it’s back to real-world testing behind the wheel.

Dampers

There are about 30 to 40 individual shims that help provide the damping performance inside a passenger car damper (which is often known as a ‘shock absorber’).

Each of these shims can have between five and 10 different variations. This means more than a million combinations are possible for the damper code, or the specific settings inside a damper.

We fine-tune this combination inside the damper to achieve the best ride and handling balance.

To do this, we use specially designed take-apart suspension dampers we can change internally during development and testing – both in our prototype workshop and on the road.

We test these changeable prototype dampers in various testing settings. Depending on the type of vehicle, this could be on a racing circuit, on an off-road 4×4 track, a proving ground, or a remote test area. It could be a combination, or even all of these.

We verify the performance of these dampers and their intricate settings on our damper dynamometer. This specialist calibrated device operates on a test bench. It repeatedly compresses and extends a suspension damper at set speeds and then measures its resistance and movements according to different loads. It measures a damper’s force velocity in tiny increments each second.

It’s a critical piece of testing kit. Even F1 teams and their suspension suppliers use them.

Once the dampers’ performance achieves the correct measured curve, each damper goes back in the test vehicle and on-road testing resumes.

Our damper dyno unit is mobile. We take it with us during confidential vehicle testing, even in the most remote parts of outback Australia.

Fun fact: our damper dyno is hidden inside a specialised trailer, a type that has nothing to do with the automotive world. (You’ll never guess what it is.)

Jounce bumpers

These are also called ‘bump stops’. Jounce bumpers play an extra-important role in 4×4 vehicles.

Jounce bumpers are vital because they limit the maximum movement of the suspension parts.

When the suspension reaches its maximum compression, the loads being pushed through the wheel often want to keep going into the car’s frame. The jounce bumper takes up this load.

Managing this transition of (often huge) forces from the suspension to the jounce bumper is vital. These small devices ensure the impacts into the vehicle’s body become controlled and slow.

This controlled transition helps prevent vehicle damage. It also helps prevent the occupants feeling the uncomfortable NVH (noise, vibration and harshness) these loads can send into the vehicle’s cabin.

When developing jounce bumpers as part of a carmaker’s suspension tuning program, we model their ideal performance curve in ADAMS simulation software. These curves determine the all-important gradual transition of suspension-induced forces.

Following this, we develop prototype units with our suppliers. The shape, length and construction of the bumper is developed to meet the curve.

Then it’s (you guessed it) back to testing.

The final stage involves fine-tuning the bumper’s material composition. Once approved by the carmaker, they’re ready for production and fitment.

Testing, testing, 1,2.3… 99, 100.

Testing counts.

Those hundreds of suspension tuning drives and hours in the prototype workshop can be the difference between a great vehicle and an exceptional vehicle, the kind that thousands of new-car buyers end up choosing.

All of our suspension development and enhancement programs are done according to new-car development processes. The world’s biggest and most experienced automakers use these processes.

Testing not only makes the final product better. It can create breakthroughs.

Here’s an example.

For one carmaker’s suspension development program, we developed a multi-stack valve design for their dampers. It allowed us to add extra low-speed damping alongside better high-speed damping control.

This meant much better ride performance across a wider range of speeds and road surface irregularities.

We were only able to do this because we discovered this opportunity during testing.

Once again, testing counts.

Trust the process

If you’re a Science Type, you’ll see there are lots of independent variables involved in new-car suspension tuning.

It’s made more complex by the fact these variables interact so closely with each other.

But when you’ve delivered localised suspension tuning programs for carmakers for almost 30 years, the process is straightforward.

It’s all about correct vehicle evaluation, performance bandwidths, identifying deficiencies, establishing technical targets, and then (mechanically) designing the right componentry and the tuning paths needed to achieve these targets. And – you guessed it – testing.

You need to push every suspension attribute to its limit – and sometimes past its limit – to help establish how close you are to the optimum solution.

But the results are worth it, especially for new-car buyers and car company CFOs.

Build global, tune local

Big carmakers develop and build ‘World’ cars and ‘Regional’ cars according to mass manufacturing business plans.

It’s an effective approach. It underpins almost every carmaker’s commercial success.

But localising specific characteristics in selected new-car models can dramatically change a brand’s sales and financial results in certain markets.

Tuning a model’s ride and handling for local conditions can transform not only how it handles a particular country’s roads, it can also change how buyers perceive that vehicle against its competitors.

This is a huge advantage for a carmaker.

Certain new-car brands use Premcar’s strategic agility to create this advantage.

They know this advantage often isn’t possible as part of a model series’ global product plan. But they know they can create it with us.

It’s worth it: the commercial effects are far greater than the investment.

Hyundai and Kia have been doing this in Australia for years. So has Nissan and plenty of other brands we can’t mention.

These brands all have one thing in common: they ride all year long on a unique and proven competitive edge.

Their customers know it. Their dealers know it. And the national media know it.

Peter Drucker is right

Marketing takes many forms.

Product marketing is arguably the most powerful.

It’s evidence-based, it’s tangible, and in the case of new cars with locally tuned suspension systems, it can be experienced.

Peter Drucker said the role of marketing is to create and retain customers.

Brands attract people. Discounts and finance offers might turn some of them into buyers. But a compelling product is far more likely to capture and retain them as customers.

If you’re a new-car importer struggling to capture more customers without price discounts and incentives, is there any better way than a local enhancement program to show a buyer you’ve gone out of your way to meet their needs and desires?

Remember: the price difference between off-the-rack and made-to-measure is smaller than you might think.

But their biggest difference is this: One of them constantly attracts more customers. And that’s the basis of a sustainable business.

Bernie Quinn – Engineering Director, Premcar Pty Ltd

About Premcar:

Premcar Pty Ltd is a leading Australian vehicle engineering business that specialises in the automotive, defence and aerospace industries. For more than 25 years, global car-makers have made Premcar their go-to partner for the complete design, engineering and manufacture of niche-model new cars, full-scale new-vehicle development programs, and electric vehicle (EV) conversions and manufacturing. Premcar’s body of work is extensive. It is the name behind more than 200,000 new cars and 55,000 new-vehicle engines. The company has delivered technical advancements and sales success for major car brands from Europe, the USA, Japan, China and Australia. Visit premcar.au.

Follow Premcar on Instagram – @premcaraustralia

Follow Premcar on LinkedIn – @Premcar Pty Ltd